High Speed USB Output PX409 Series Pressure Transducer |

| PX409-USBH Series |

|

|

|

|

|

|

|

¥

7,835.00

PX409-015GUSBH

|

| • |

FAST DELIVERY!

|

| • |

High Speed USB Pressure Sensor! 1000 Reading/Second

|

| • |

Free Downloadable Software

|

| • |

Micro-Machined Silicon Sensor

|

| • |

316L SS Wetted Parts

|

| • |

High ±0.08% BSL Accuracy

|

| • |

Excellent Long Term Stability

|

| • |

USB 2.0 and Below Compatible

|

| • |

Standard USB Connector Termination

|

| • |

Shock and Vibration Rated

|

| • |

Ruggedized with Secondary Containment

|

| • |

New PX409 USBH Product Release With Upgraded High-Speed Software!

|

View related products - Pressure Transducers

|

| |

|

|

|

|

The PX409 High-Speed USBH Series connects directly

to your computer. Free software makes data logging and charting your readings a simple task. Also included are .NET drivers and a command set for command line access. The micro-machined silicon design is ideal for pressure or level applications in laboratory, test platforms, or bio/pharmaceutical applications as well as industrial applications that require a rugged, high accuracy transducer. This sensor provides a very stable transducer with an exceptional high accuracy of ±0.08% and a broad compensated range of -29 to 85°C (-20 to 185°F). The modular construction allows for fast delivery of most configurations and fittings.

FREE OMEGA™ Downloadable Software!

Free OMEGA PC software takes the data from the transmitter directly to the digital domain, turning your laptop or Windows® tablet into a virtual meter, chart recorder, or data logger. Also included are .NET APIs and a command set for command-line access. Help files are available after installation with the most update to date information.

Download your free copy today!

(Includes software to run TRH Central compatible devices).

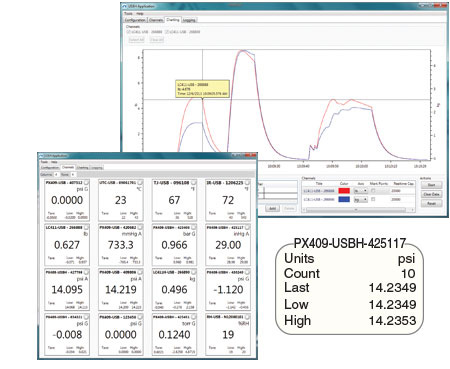

Charting Window – The addition of a charting window allows you to see your data graphed in real time. The Y axis is configurable to allow simultaneous graphing of multiple engineering units. You can output the image of your data to a png file. Charting Window – The addition of a charting window allows you to see your data graphed in real time. The Y axis is configurable to allow simultaneous graphing of multiple engineering units. You can output the image of your data to a png file.

Channels Window - Display data from all of your sensors simultaneously. Each channel has configurable user alarms, three data filters, tare, resettable low/high indication, and sample rates ranging from 30 minutes to 1000Hz.

Logging Window – A new xls filetype output option presents preformatted data for readability. In addition, Live Statistics are displayed, including the sensor information, the start/stop time, the number of samples taken, the current reading, and the High/Low readings. With the logging window, you can capture your data for later analysis.

SPECIFICATIONS

Accuracy: 0.08% BSL (linearity, hysteresis and repeatability combined)

Resolution: Up to 5.5 significant figures

Zero Balance: ±0.5% full scale typical ±1% maximum (±1% typical, ±2% maximum for 2.5 psi and below)

Span Setting: ±0.5% full scale typical ±1% maximum (±1% typical, ±2% maximum for 2.5 psi and below). Calibrated in vertical direction with fitting down

Temperature Compensation (Over Compensated Range):

Span: Range > 5 psi: ±0.5%

Range ≤5 psi: ±1.0%

Zero: Range > 5 psi: ±0.5%

Range ≤ 5 psi: ±1.0%

Minimum Isolation:

100 MΩ @ 50 Vdc case to sensor

2 MΩ @ 50 Vdc case to output terminations

Pressure Cycles: 1 million, minimum

Long Term Stability (1-Year): ±0.1% full scale typical

A to D Conversion: 24-bit

Shock: 50 g, 11 mS half sine, vertical and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute cycle, Curve L, Mil-Spec 810 figure 514-2-2, vertical and horizontal axis

Bandwidth: DC to 1000 updates per second typical (±3%)

Power Consumption: 0.35 W typical

CE Compliant: Meets industrial emissions and immunity EN61326

Environmental Protection: IP65

Secondary Containment

Gage/Vacuum/Compound Pressure:

10 inH2O to 5 psi: to 1000 psi

15 to 1000 psi: to 3000 psi

1500 to 5000 psi: to 10,000 psi

Absolute/Barometric Pressure:

5 to 1000 psi: to 6000 psi

1500 to 5000 psi: to 10,000 psi

Overpressure

Gage/Vacuum/Compound Pressure

10 inH2O: 10 times span

1 psi: 6 times span

2.5 psi to 1000 psi: 4 times span

1500 psi yo 5000 psi: 7250 psi maximum

Absolute/Barometric Pressure:

5 psia: 6 times span

15 psia to 1000 psia: 4 times span

1500 psia to 5000 psia: 7250 psia maximum

Wetted Parts: 316L stainless steel

Weight: 200 g (7 oz)

Operating Temperature Range: -40 to 85°C (-40 to 185°F)

Compensated Temperature:

Ranges >5 psi: -29 to 85°C (-20 to 185°F)

Ranges ≤5 psi: -17 to 85°C (0 to 185°F)

|

|

|

|

|

|

† Price are shown in RMB.

Note: Comes complete with 5-point NIST traceable calibration certificate, downloadable digital readout, logging software, .NET drivers and command set.

|

|

|

|

|

|

|

|

|

Part Number Builder |

|

|

|

|

|

|

|

|

Option Descriptions

|

|

(1)

|

Pressure Range (PSI)

|

| |

Select

-10W for 10"H2O

-001 for 0-1 psi

-2.5 for 0-2.5 psi

-005 for 0-5 psi

-015 for 0-15 psi

-030 for 0-30 psi

-050 for 0-50 psi

-075 for 0-75 psi

-100 for 0-100 psi

-150 for 0-150 psi

-250 for 0-250 psi

-500 for 0-500 psi

-750 for 0-750 psi

-1.0K for 0-1000 psi

-1.5K for 0-1500 psi

-2.5K for 0-2500 psi

-3.5K for 0-3500 psi

-5.0K for 0-5000 psi

-16 for 16 to 32 inHg (Barometric only)

-26 for 26 to 32 inHg (Barometric only)

-32 for 0 to 32 inHg (Barometric only)

|

(2)

|

Type

|

| |

Select

G for Gage

A for Absolute (15 to 5000 psia)

CG for Compound Gage (10W to 15 psi only)

V for Vacuum (Negitive gage)

B for Barometric Pressure

DWU for Wet/Wet Unidirectional Differential

WDU for Wet/Dry Unidirectional Differential

|

(3)

|

Output

|

| |

Select

USBH for High Speed USB

|

|

NOTE: All combinations may not be valid, check spec sheet for valid part numbers.

|

| |

|

|

|

|

|

|

|  |

|

Related Links -

Related Products

|

|

|

|

|

|

|

|