Explosion Proof / Intrinsically Safe Industrial Pressure Transmitter |

| PX880 |

|

|

|

|

|

|

|

¥

9,950.00

PX880-015GI

|

| • |

Explosion Proof FM & CSA Ratings

|

| • |

Intrinsically Safe CSA Ratings

|

| • |

Miniature Size

|

| • |

±0.25% Accuracy

|

| • |

All Welded 316 Stainless Steel Construction

|

| • |

Zero & Span Adjustability

|

| • |

Full 5:1 Range Turndown

(on ranges ≥100 psi)

|

| • |

4-20 mA Output

|

View related products - Pressure Transducers

|

| |

|

|

|

|

The PX880 Series comprises the

most compact, durable, accurate,

cost-effective, full-featured pressure

transmitters available. The 4 to 20

mA output is standard, with a

12 to 48 Vdc power supply.

Designed for stable performance

in the toughest environments, with

316 SS welded construction, PX880

transmitters are ideal for use with

corrosive media and in hazardous

environments.

Both models have FM and CSA

Explosion Proof and CSA Intrinsically Safe approvals and

meet NACE standards for offshore

applications (The PX880-150WCGI, 0-75 to 0-150 inches of water range does not have FM approval, only CSA Intrinsically Safe approval).

With the cover retained

by a stainless steel chain and no

internal jumpers for span turndown,

losses due to misplaced or dropped

parts are eliminated.

The small size and light weight of

both models eliminate any

complicated mounting hardware or

mechanical supports, which reduces

installation time substantially. The

integral junction box permits simple

field wiring without the need for

additional hardware, and adds to

the speed and ease of installation.

OPERATION

The heart of the PX880 pressure

transmitter is a silicon piezoresistive

sensing chip. This miniature

microetched semiconductor gives a

voltage output proportional to the

applied pressure. The chip is

isolated from the process media by

a stainless steel diaphragm.

Silicone oil is used to transmit the

process pressure to the sensor.

An amplifier PCB enclosed in a

sealed chamber is used to convert

the millivolt signal from the sensor

to a calibrated 4 to 20 mA

transmitter output. Feed-throughs

for EMI and RF protection are used

between the amplifier board and the

terminal housing.

Each transmitter is tested over both

pressure and temperature ranges.

A compensator circuit is used to

bring the output of the sensor into

specification. After compensation,

every transmitter is tested a second

time for pressure and temperature

effects to ensure that it meets

performance specifications. The

transmitters are calibrated to

the upper ranges listed in the order

box, but end users can recalibrate

them to different ranges.

Recalibration is done via 3 screw

potentiometers inside the

transmitter’s head. Recalibrating to

any range between the 2 listed

for a particular sensor can be

accomplished with a known

pressure source.

The PX881 is flush diaphragm

pressure transmitter, designed to

mount flush against process media

and to prevent any media particles

from collecting at the diaphragm.

SPECIFICATIONS

Excitation: 12 to 40 Vdc with reverse polarity protection

Output: 4 to 20 mA (2 wire)

Accuracy: ±0.2% of calibrated span including linearity, hysteresis and repeatability

Max Loop Resistance: 600 Ω @ 24 Vdc max Ω = (supply voltage - 12) x 50

Storage Temperature: -40 to 100°C (-40 to 212°F)

Operating Temperature: -40 to 100°C (-40 to 212°F)

Compensated Temperature: -29 to 82°C (-20 to 180°F)

Thermal Effects: Zero and span combined ±0.02% upper range/°F (30 to 130°F) ±0.032% upper range/°F (-20 to 180°F)

Proof Pressure: 200% upper range

Stability: ±0.5% of upper range for 6 months

Vibration: 0.1% upper limit for 3 g @ 200 Hz

Approvals: FM Explosion Proof for Class 1, 2, 3 Div 1, Groups B, C, D, E, G NEMA 4 enclosure) CSA (Intrinsic Safety for Class 1, 2, 3, Div 1 Groups A, B, C, D, E, F, G; Explosion Proof for Class 1, 2, 3 Div 1, Groups B, C, D, E, F, G Enclosure 4)

Wetted Parts:

PX880: 316 SS

PX881: 316 SS, PTFE gasket and Hastelloy diaphragm

Pressure Port:

PX880: 1/2 NPTF

PX881: Weldolet pipe coupling

Electrical Connection: 1/2 NPTF

Body Material: 316 SS

Cast Head: CF-8M (316 cast SS) with Buna-N O-ring

Fluid Fill: DC 200 silicone oil

Response Time: 20 ms

Weight: 725 g (1.6 lb)

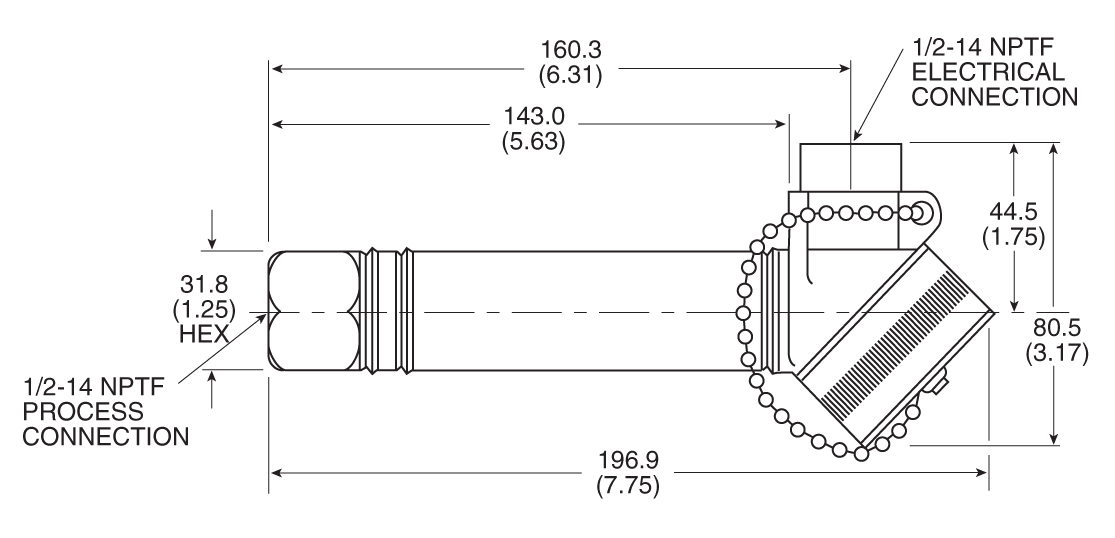

PX880 ½ NPT Series

Dimensions: mm (inches)

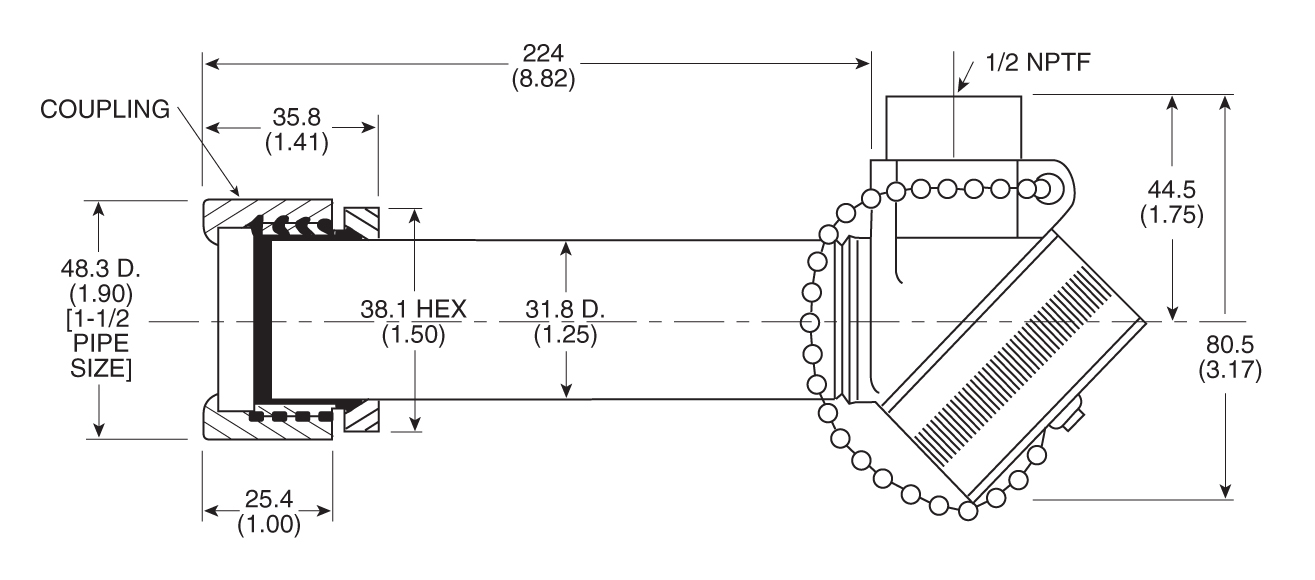

PX881 Flush Mount Series

PX881 Flush Mount Series

Dimensions: mm (inches)

|

|

|

|

|

|

† Price are shown in RMB.

Note: Units are shipped calibrated to highest range.

PX881 flush diaphragm models requires PX881-CPL weld on coupling.

Ordering Example: (1) PX881-030GI is a flush mount Transmitter with a 0-15 to 0-30 psig range, ¥11,635.00, plus (1) PX881-CPL weld on coupling for PX881, ¥430.00, ¥11,635.00 + 430.00 = $12,065.00

|

|

|

|

|

|  |

|

Related Links -

Related Products

|

|

|

|

Related Products

|

|

PX835 Series:

|

Explosion Proof / Flame Proof and IS Rated

Pressure Transmitter for Hazardous Locations

|

|

|

|

|

PX831 Series:

|

|

Explosion Proof Pressure Transmitter For Hazardous Locations 316 SS Construction

|

|

|

|

|

PX832 Series:

|

|

Explosion Proof Pressure Transducer for Hazardous Locations, 316SS Body

|

|

|

|

|

|

|

|

|

DP24-E:

|

|

1/8 DIN Economical Process Meter - Discontinued

|

|

|

|

|

|

|

DP41:

|

|

1/8 DIN High Performance Temperature, Process and Strain Meter

|

|

|

|

|

|

|

|

|